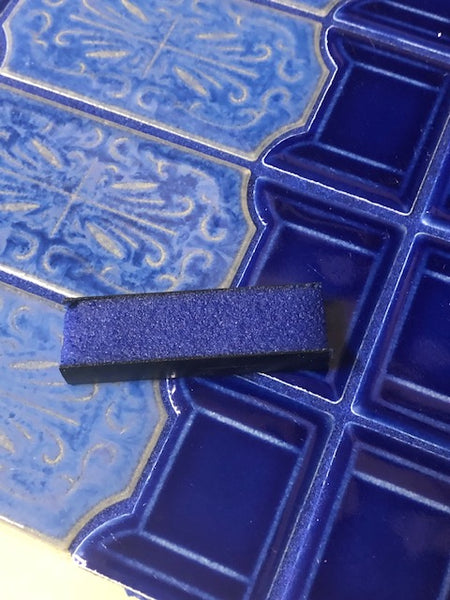

Endurance 1500 is a Professional Grade Epoxy Grout

PRODUCT DESCRIPTION:

Endurance E-1500 is an epoxy grout system that meets the requirements of ANSI A118.3, it's chemical resistant, and water clean-up during installation.

Each kit comes packaged in a plastic bucket that can be used for mixing the grout. You will receive parts A, B, and C, all packaged inside the bucket. We only ship our epoxy grout products by UPS Ground, and Next Day options are not available due to the reactive nature of the epoxy when mixed together.

Uses: E-1500 is a three-part 100% epoxy solids system for grouting of ceramic tile, porcelain tile, glass tile, floor brick, quarry tile, pavers and mosaics. It is recommended for use in restaurants, hospitals, food prep areas, counter-tops, back-splashes, tub and shower areas, outdoor fountains, swimming pools, saunas, steam rooms, etc. where high exposure levels of organic acids are not present. Cleans up with water before grout sets. Allow up to 10-14 days for full cure before filling a pool or fountain that submerges the grout.

Limitations: Not for use in applications that requires steam cleaning or where harsh chemicals are used to clean the surface of the tiles and grout. Not for environments above 230°F for any extended periods of time.

WORKING CHARACTERISTICS: E-1500 is ideally installed at temperatures from 65F to 80F. At higher temperatures, the pot life, open time and clean-up time are reduced. At lower temperatures, these factors are reversed. Working surface temperature can vary from room temperature and should be taken into consideration. For best results, do not begin application of E-1500 until the temperature of the room and substrate is above 50F and rising. Maintain a temperature of 65 F or higher during the curing period. E-1500 may be stored at low temperatures, but not below 32 F, if the epoxy is allowed to freeze, it will need to thaw out and brought up to room temperature before using.

PROTECTING NEW TILEWORK: To avoid damage to finished tile-work, schedule floor installations to begin only after all structural work, building enclosure and overhead finishing work, such as ceilings, painting, mechanical and electrical work are completed. Keep all traffic off of finished tile floors until it has fully cured or provide up to ¾” thick plywood protection over Kraft paper to protect floors before installation materials have fully cured.

PACKAGING: E-1500 is available in an 11 lb. (5.0 kg) kit, which include resin (A) and hardener (B), and colored aggregate powder (C). The system consists of three components, Parts A, B, and C, which are packaged in a plastic bucket.